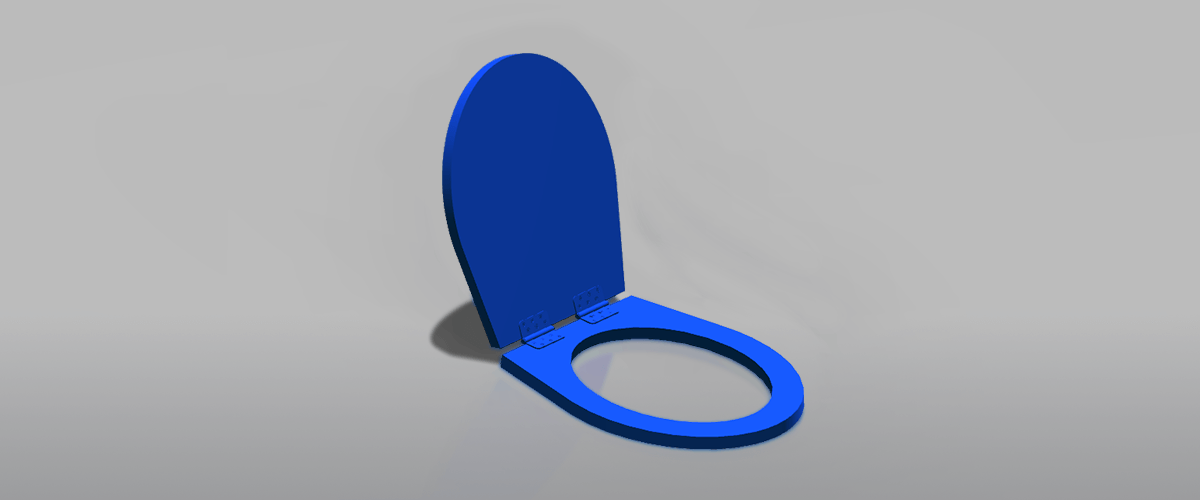

The US Air Force has just announced it can now 3D print aircraft parts. So what was the first thing they printed? A toilet seat of course!

3D printing

3D printing the toilet cover saved the US Air Force around $9,700....

There are only 3 people certified to use the printer and only one 3D printer in service. Located at the Travis Airforce Base California. They can only produce non-structural parts.

Why a toilet seat?

It might not be pretty, but 3D printing this toilet cover saves the US Air Force around $9,700 (€8,832) a time.

Latrine covers, the first aircraft parts authorized for use after being printed on the Stratasys F900 three-dimensional printer are on display Aug. 15, 2019, at Travis Air Force Base, California. Travis AFB is the first field-unit location in the Air Force to have the Stratays F900 3-D industrial printer certified by the Federal Aviation Administration and Air Force Advanced Technology and Training Center for use on aircraft replacement parts. (U.S. Air Force photo by Louis Briscese)

That's because the part is fitted to a C-5 Galaxy, a 1960 military cargo plane. The last C-5 Galaxy was produced in 1989 and they're still in service. The part needs to be custom made and reverse engineered as the plane's manufacturer no longer produces this part, bringing the cost of replacing this particular part to a whopping $10,000 (€9105) a time! The new, 3D printed toilet cover costs just $300 (€273).

The latrine covers we just printed usually take about a year from the time they've been ordered to the time they've been delivered, we printed two of the covers in 73 hours. -- Master Sgt. John Higgs, 60th MXS aircraft metals technology section chief.

US Airforce C-5 Galaxy Robert Couse-Baker

3D printing for the US Air Force

On August 19, 219, the USAF proudly announced that it is now able to produce 3D printed (non-structural) parts for airplanes, saving potentially millions for the air force. The Travis Airforce Base, California is the first field-unit location in the Airforce to produce 3D printed parts. Currently, only 3 members of staff are authorized to use the printer.

This may come as surprise to many given that NASA has it's own additive manufacturing department and a bioprinter on the International Space Station has been in service since 2018, but the US Air force has extremely tight restrictions on how things can be produced. Yes, even toilet seats!

They are using a Stratasys F900 3D industrial printer that uses an Ultem 9085, a flame-retardant plastic medium.

Why not 3D print your own toilet seat?

It's easy with BricsCAD Shape. Download free for life at www.bricsys.com. Then make the effortless move to BricsCAD BIM. Freedom of choice, plus perpetual (permanent) product licenses that work with all languages, in all places. You'll love what we've built for you with the BricsCAD® product family.